Eco-Friendly Fibers and Organic Fibers

Characteristics and difference between eco-friendly fibres and organic fibres | type of eco-friendly fibers | eco-friendly fiber names

Textiles Industry has many working procedures which form flow processes. Each process makes various influences on the environment and human health.Therefore, many eco-friendly fibers have been invented which do not require the use of any pesticides or chemicals eg. bamboo, hemp, Ramie, mud silk etc.

Textiles Industry has many working procedures which form flow processes. Each process makes various influences on the environment and human health. Therefore, many eco-friendly fibres have been invented which do not require the use of any pesticides or chemicals eg. bamboo, hemp, Ramie, mud silk etc.

All natural fibres are not Eco-friendly Fibers

Natural fibre, such as cotton fibre is free of impurities but only when no harmful pesticides or insecticides are used in its cultivation. If so, then it is environmentally friendly. However, even if they are produced sans any of these harmful substances, they can become ‘polluted’ when processed for making yarns and fabrics because of all the textile chemicals used on them.

Same is the case with animal fibre like wool which can get contaminated due to pesticides used in sheep dips or a variety of drugs used for treating animal diseases. However, when the plant fibre, cotton for example once again, is cultivated without any harmful pesticides and with the help of composted manures and cover crops then only can it be said ‘organic cotton’ which is 100% eco-friendly fibre.

Man-made fibres can also be Eco-friendly Fibers

Natural fibres are obtained from plants (such as cotton, hemp, jute etc.), from animals (such as wool, fur etc.), or insects (such as silk). Man-made fibres can be divided into two categories synthetic fibres and regenerated fibres. Synthetic fibres are completely made from chemicals like polyester fibre or nylon fibre. Regenerated fibres are made by transforming natural polymers through the chemical-based process.

These fibres again have two categories – one having protein origin and the other with cellulose origin. Regenerated fibres of protein origin come from plant protein such as corn, soy, peanut etc. or from animal protein such as casein from milk. Regenerated fibres of cellulose origin come from the cellulose of wood pulp or leaves.

Examples of such fibres are bamboo, rayon, lyocell, tencel, viscose etc. Thus, these man-made regenerated fibres (some of which are sometimes called synthetic fibres like rayon), are also eco- friendly fibres.

Ecology

The eco-problems in textile industry occur during some production processes and are carried forward right to the finished product. Controlling pollution is as vital as making a product free from the toxic effect. There is a need to produce the material which is eco-friendly. So, the materials can be considered ‘environmentally friendly for a variety of reasons’.

The chemicals used which are responsible for polluting air are chlorine gas, acetic acid fumes, kerosene, diazotisation fumes, acid fumes etc. A new parameter that today increasingly vital is ecology. With respect to clothing & textiles the phrase ‘Ecology’ can be classified into:

-

Production ecology

This refers to the process of production and manufacture of fibers, textiles, and garments which should be environmentally friendly and should satisfy the rational conditions for the conservation of air purity, water purity, waste treatment, and for the protection against noise.

-

Human ecology

Effect of textiles has on the user, apparels next to skin on health. The concentration of substances which, according to the present knowledge, could induce dangerous effects on humans during normal use must be avoided in the textiles.

-

Disposal ecology

Effect of textile waste (solid as well as liquid) on a clean environment. Sustainable Textile is a pattern of resource use that aims to meet human needs while preserving the environment so that these needs can be met not only in the present but also for generations to come.

Since, the very idea of sustainable development revolves around the progress which is taking place in the present, keeping in mind the future, somewhere. Since eco-textiles are the need of the hour and also are of the primary goals of millennium development goals in sustainable environmental development.

What are Eco-Friendly Fabrics?

Eco-friendly fabrics are made from fibres that do not require the use of any pesticides or chemicals to grow. They are naturally resistant to mold and mildew and are disease free. Hemp, linen, bamboo, and ramie are ecofriendly fibres.

Why Go Organic or EcoFriendly?

Social responsibility: Chemicals and pesticides invade drinking water and groundwater, polluting its fish and even reaching human consumption. Organic and eco fibres grow without any pesticides or chemical fertilizers.

Biodegradable: Eco and organic fabric biodegrade naturally over time. Synthetic fibres eventually become waste and let off harmful toxins when they degrade.

Health: Many people are allergic or dislike wearing synthetic textiles. Eco fabrics have all the properties of the new synthetic breathable fibres with added softness and drape. They feel better against the skin.

Absorption: Not only do its chemicals reach the groundwater, but conventional clothing is also worn next to the most porous organskin.Organic and ecofibers are natural and do not contain irritating chemicals. Many of them are also considered

hypoallergenic and naturally antibacterial.

Popularity: Organic foods have been around for a while and it is a natural evolution that organic and eco-friendly fabrics will also gain popularity. Eco and Organic fabrics once considered an alternative is now entering into the mainstream.

Some Eco-Friendly Fibers

-

Aloe Vera

In addition to the skin benefits, aloe also adds a few interesting features to the fabric itself; it is naturally anti-bacterial, and so not only does it keep clothing cleaner, but it also combats body odor. It is proving to be an exciting and beneficiary fibre for the wearer.

In addition to the skin benefits, aloe also adds a few interesting features to the fabric itself; it is naturally anti-bacterial, and so not only does it keep clothing cleaner, but it also combats body odor. It is proving to be an exciting and beneficiary fibre for the wearer. -

Bamboo

Bamboo is one of nature’s most sustainable resources; it’s 100% biodegradable and is naturally regenerative. Bamboo grows extremely fast, up to one foot a day!

After taking from the plant, the bamboo is spun into yarns with no chemical modification by crushing the bamboo plant and then using natural enzymes to break the bamboo walls into a pulp so that the natural fibres can be mechanically combed out and spun into yarn by undergoing various processes.

Bamboo fabric made from this process is sometimes called bamboo linen. Bamboo fabric is naturally antimicrobial, hypoallergenic and thermal regulating. It is also resistant to mold.Bamboo breathes and wicks moisture away due to its porous nature. Bamboo also has an excellent drape and a silkycashmere feel.

-

Bamboo Viscose

The other way to manufacture Bamboo is chemical, by regenerating the cellulose fibre, which makes Bamboo Viscose.

All fabrics manufactured with cellulose, whether its bamboo, plants or trees are rayon (viscose).

Bamboo Viscose is considered ecofriendly, as the primary source is naturally regenerative.

-

Banana

These fibres are bonded by natural gums and made of thickly walled cell tissues. Normally two to three outer sheaths are removed, and the intermediate layers are used. The outer layer of the plant gives coarse fibres that are very brittle and the innermost sheaths are also rejected as they contain pulpy matter. It can be easily blended with cotton or other synthetic fibres.

These fibres are bonded by natural gums and made of thickly walled cell tissues. Normally two to three outer sheaths are removed, and the intermediate layers are used. The outer layer of the plant gives coarse fibres that are very brittle and the innermost sheaths are also rejected as they contain pulpy matter. It can be easily blended with cotton or other synthetic fibres. -

Coir

These fibres have high lignin and low cellulosic content. Extracted fibres are spun into durable yarn, mostly with a brownish hue. They are lightweight, resilient, and durable. Fibres extracted from activated carbon of coconut shells are known as Cocona fibres.

These fibres have high lignin and low cellulosic content. Extracted fibres are spun into durable yarn, mostly with a brownish hue. They are lightweight, resilient, and durable. Fibres extracted from activated carbon of coconut shells are known as Cocona fibres. -

Corn

Corn fibre has already threaded its way into some winning outfits produced by designers from across the globe. Corn fibre manufacturers have claimed that these fibres can be used for sportswear, jacket, outer coat, apparels etc.

Corn fibre has already threaded its way into some winning outfits produced by designers from across the globe. Corn fibre manufacturers have claimed that these fibres can be used for sportswear, jacket, outer coat, apparels etc. -

Hemp

Having the most ecofriendly potential, these plants grow quickly and densely which makes it difficult for weeds to hold on no pesticides or herbicides needed. Hemp does not exhaust the soil and enables sustainability by leaving the soil in excellent condition for any succeeding crops.

Hemp has long fibres perfect for spinning with minimum processing and because it comes in a variety of weights and textures it can be used to produce many different articles of clothing/accessories.

Hemp is an extremely durable fabric. It is also very insulating, absorbent and improves over time with washing and wearing. It reveals a new surface becoming softer with every wash. It is also UV resistant, highly breathable, fast drying, hypoallergenic and nonirritating to the skin.

-

Jute

Due to its texture initially, it was processed by hand. It is the second most important vegetable fibre after cotton, in terms of usage, global consumption, production and availability. Jute fibres are used for making carpet, apparel, composites, upholstery furnishings, decorative colour boards. Non-woven jute fabrics carry applications in meditech, agrotech, protech, geotextiles and many.

Due to its texture initially, it was processed by hand. It is the second most important vegetable fibre after cotton, in terms of usage, global consumption, production and availability. Jute fibres are used for making carpet, apparel, composites, upholstery furnishings, decorative colour boards. Non-woven jute fabrics carry applications in meditech, agrotech, protech, geotextiles and many. -

Pineapple

Pineapple fibres are blended well with other fibres. Fabrics made from pineapple fibres have an elegant appearance. After many inventions, pina fabrics can rightly be commended as heirloom textiles used for hometech, auto mobitech, and geotech.

Pineapple fibres are blended well with other fibres. Fabrics made from pineapple fibres have an elegant appearance. After many inventions, pina fabrics can rightly be commended as heirloom textiles used for hometech, auto mobitech, and geotech. -

Ramie

Ramie is a highly sustainable ecofriendly fibre. It is very strong and durable and is 8 times stronger than cotton and even stronger when wet.

Ramie is a flowering plant, and once the flowers begin to bloom, that is when the fibres are extracted from the plant for spinning, it can be harvested up to 6 times in a successful year!

Ramie is naturally resistant to bacteria, mold, and mildew as well as light damage, rot or insect attack. It does not require pesticides or herbicides to grow healthily.

-

Seacell

This fibre is derived from wood pulp and seaweed (algae) that, actually diffuses its protective and anti-inflammatory properties into the skin, stimulating the metabolism. It’s like clothes are living! Totally intriguing. It contains microscopic particles of marine algae fibre that aid in cellular regeneration.

-

Lenpur

This biodegradable fabric is made from white pine tree clippings, and “offers the comfort of silk, the touch of cashmere and the lightness of linen.” Lenpur is a cut above the other cellulose fibres due to its softness, its absorption capacity and ability to release dampness, and its ability to sustain a higher thermal range — thus keeping you cooler in the summer and warmer in the winter.

-

Lyocell

This fibre is made from the biodegradable wood pulp using chemical-free processes. Non-toxic solvents are used in its production and then recycled, creating a manufacturing process with very little byproduct. (However, it sounds like it still uses a ton of energy, so it’s not perfect.) It can be blended with other fibres to create fabrics like SeaCell (Lyocell and Seaweed, shown above) and Hempcel (Lyocell and Hemp).

-

Soy Silk

This lesser known 100% biodegradable eco-friendly fabric is made from tofu-manufacturing waste. Soy protein is liquefied and then stretched into long, continuous fibres that are cut and processed like any other spinning fibre. Because soy has a high protein content, the fabric is very receptive to natural dyes, so there’s no need for synthetic dyes.

-

STINGplus Nettle Fabric

This fabric may be the most sustainable fabric ever. The fabric is woven from the stinging nettle, which “produces a uniquely strong, soft and naturally fire retardant textile fibre” and, blended with pure new wool, it is “the ultimate environmental upholstery solution.”

Influences of textile/clothing production on the environment

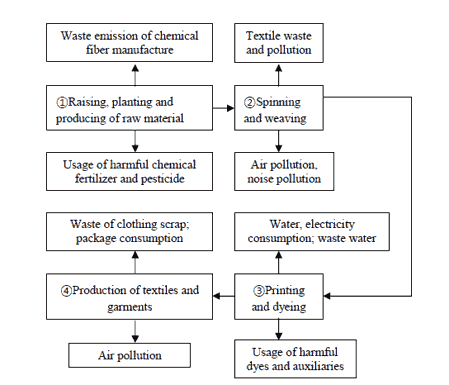

Textile and clothing is a labour-intensive industry. It has many working procedures which form flow processes. Each process makes various influences on the environment and human health. The concrete effects are shown in the figure below

Among all the above factors, the environment influence includes exhaust fumes and wastewater, materials pollutions, consumption of energy and water. Those harmful to human safety and health include excessive use of pesticides and formaldehyde and other chemicals, noise pollution and air pollution in textile and clothing plants.